Fully degradable composite implant materialsare highly desirable in the treatment of damaged or defective bone tissue. Existing non-degradable implants experience many limitations with, for example, miss-match of mechanical properties (i.e. stress shielding), wear debris and encapsulation. Often these non-degradable implants have to be removed, requiring additional surgery that is made difficult by scar tissue. Efforts to address these issues have been made using polymer materials but to date they have suffered from insufficient mechanical properties and are bulky, making them obvious under the skin.

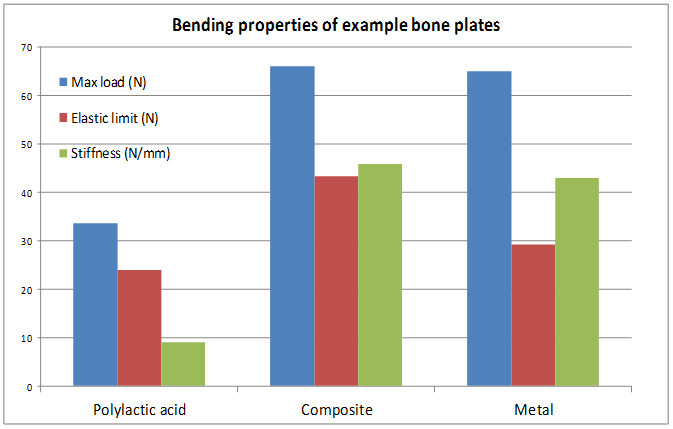

A novel bone graft material;a composite of resorbable phosphate fibres and resorbable polyesters has been developed at the University of Nottingham by a team of materials scientists, clinicians and biomedical scientists led by Professor Chris Rudd within the Department of Mechanical Materials and Manufacturing Engineering. The material addresses the need of orthopaedic surgeons for implants which provide strength and support for bony defects, then slowly degrade as they are replaced by new bone. The novelcompositematerial has significantly better mechanical properties than equivalent polymer implant materials and iscompletely resorbable. It provides good mechanical properties and low thickness profiles as would a metal but retains the formability of a polymer material. The rate at which the composite material resorbs can be tailored by modifying the constituent parts, allowing for application to different sites in the body. The material can be reformed at low-temperature, allowing for easy reshaping in theatre to specific patient requirements.

Initial applications are low-load bearing areas of bone repair. For Example: ·Orbital floor

·Cranial plates

·Retaining plates for bone filler e.g. in spinal fusion

·Jaw/cheek plates

·Finger/toe plates (or other areas of thin skin)

The university has a granted patent in Europe and US with a pending application in Japan. An additional patent has now been accepted in the US and Europe and one further patent filing has been made, expanding on the capabilities of the material.

The novel, patent protected, composite material has a number of potential benefits:

·Stiffness closely matching that of cortical bone; avoids stress shielding

·Fully resorbable; secondary removal surgery not required

·More slowly resorbed than other degradable implant materials; provides long-term support and shape maintenance with no rapid release of degradation products

·Potential for direct product replacement, with no new surgical techniques required

·Shape of implant can be optimised by surgeon in theatre using low temperature reforming

·Complex, bespoke shapes can be produced

·Can be tailored to produce an intermediate porous structure suitable for bony in-growth

·Excellent in-vitro and in-vivo results to date

由于技术保密工作限制,技术信息无法完全展现,请通过邮箱或短信联系我们,获取更多技术资料。

requiring additional surgery

professor chris rudd

low thickness profiles

specific patient requirements

biomedical scientists led